ประเภทของฟิล์มติดกระจกเพื่อป้องกันความร้อนแบ่งตามวัสดุที่อยู่บนชั้นฟิล์มได้ดังนี้

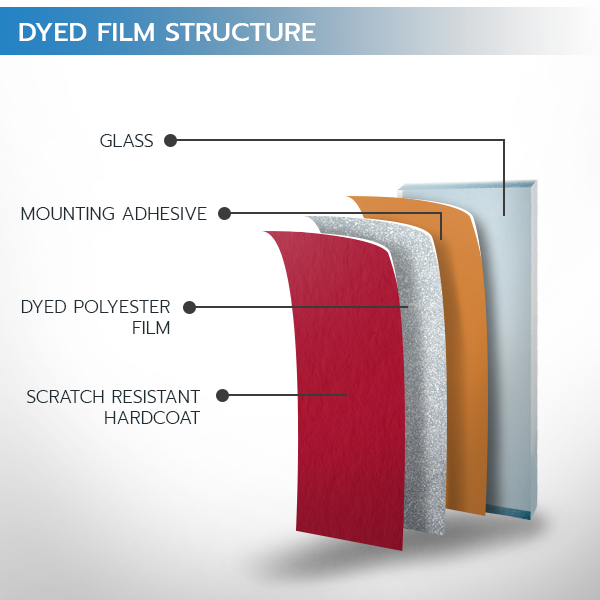

คือฟิล์มติดกระจกรุ่นแรกที่ถูกพัฒนาขึ้นมาเป็นฟิล์มที่ราคาถูกที่สุด กันรังสีของแสงด้วยสีที่ย้อมบนชั้นฟิล์มที่ถัดจากชั้นกาว จึงกันความร้อนด้วยการใช้สีบังไม่ให้รังสีความร้อนผ่านเข้ามา อย่างไรก็ตามโดยพื้นฐานฟิล์มชนิดนี้ถูกใช้เพื่อจัดการการมองเห็น มุมมองจากด้านนอก จะดูรีบทึบให้ความเป็นส่วนตัว มุมมองจากด้านในยังคงมองออกมาได้ เมื่อใช้กับหน้าต่างของรถยนต์ มุมมองจากด้านนอกจะดูดำเข้ม ข้อเสียของฟิล์มชนิดนี้คือสีจะซีดจางตามกาลเวลา และการป้องกันความร้อนของฟิล์มย้อมสีส่วนใหญ่จะไม่ดีเท่าที่ควรเพราะชั้นของสีย้อมจะดูดซับความร้อนไว้ ความร้อนบางส่วนจะถูกพาออกไปด้วยลมที่ผ่านกระจกด้านนอก ในขณะที่ความร้อนบางส่วนจะถูกถ่ายเทเข้าห้องโดยสาร

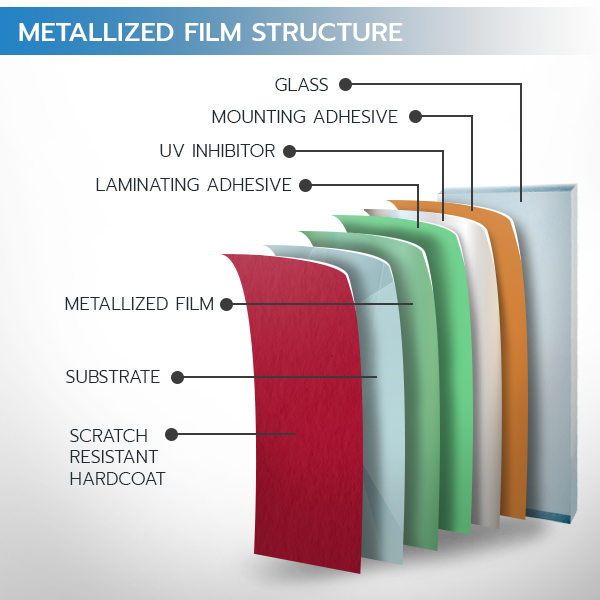

ฟิล์มประเภทนี้จะกันความร้อนด้วยวิธีการสะท้อนความร้อนของอนุภาคโลหะขนาดเล็กมากที่ฝังอยู่ในเนื้อฟิล์มและมองไม่เห็นด้วยตาเปล่า เนื้อโลหะในฟิล์มจะช่วยทำให้กระจกแข็งแรงมากขึ้น ทนทานต่อการแตกหักและกันรอยขีดข่วนมากกว่าฟิล์มย้อมสี มุมมองจากด้านนอกของฟิล์มประเภทนี้จะดูเงา ข้อเสียของฟิล์มชนิดนี้เมื่อใช้กับกระจกรถยนต์คืออาจจะสร้างแสงสะท้อนรบกวนสายตาผู้ขับขี่อื่นๆ และมีแน้วโน้มจะกีดกันสัญญาณโทรศัพท์, สัญญาณจีพีเอส, สัญญาณของบัตรทางด่วน และสัญญาณคลื่นวิทยุ หรือคลื่นแม่เหล็กไฟฟ้า

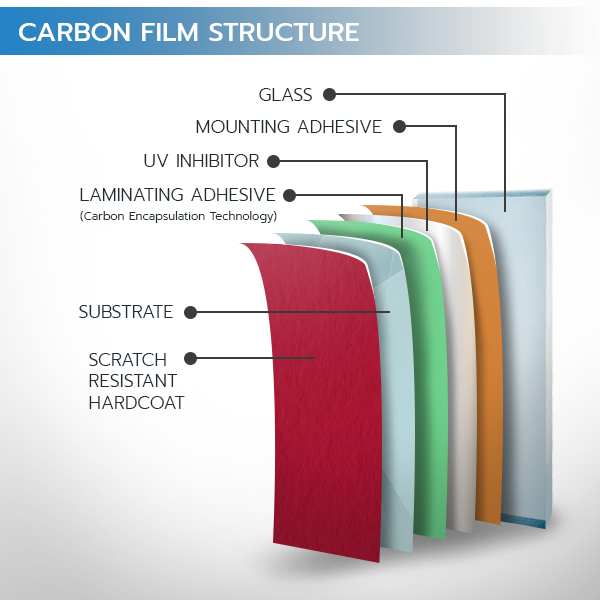

ฟิล์มประเภทนี้จะไม่มีโลหะใดๆเจือปนดังนั้นปัญหาเรื่องการกีดกันสัญญานคลื่นวิทยุหรือคลื่นแม่เหล็กไฟฟ้า หรือสัญญาณสื่อสารของอุปกรณ์อิเล็กทรอนิกส์จึงหมดไป ด้วยความเป็นคาร์บอนจึงได้สีที่เข้มและด้านทำให้ได้ความรู้สึกหรือรสนิยมที่โดดเด่นและแปลกออกไป คุณสมบัติของฟิล์มคาร์บอนจะกันรังสีอินฟราเรด (องค์ประกอบหนึ่งที่ก่อให้เกิดความร้อน) ได้ประมาณ 40% ฟิล์มคาร์บอนมีประสิทธิภาพในการป้องกันความร้อนได้ดีกว่าฟิล์มอื่นๆช่วนทำให้พื้นที่ภายในเย็น ช่วยป้องกันการซีดจางของเบาะ ลดภาระของเครื่องปรับอากาศในหน้าร้อน และมีข้อดีอีกประการคือสีจะไม่ซีดจางตามกาลเวลา

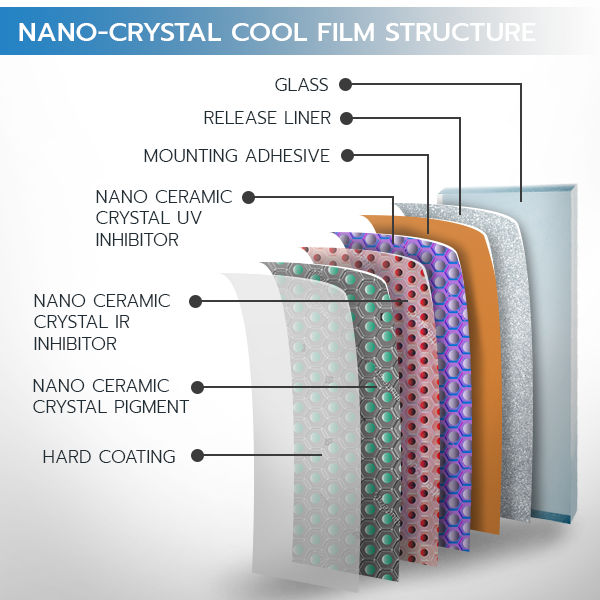

ในปัจจุบันเทคโนโลยีระดับนาโน (Nano Technology) ทำให้การผลิตหรือการสร้างวัสดุใหม่ถูกเปลี่ยนหลักการหรือแนวคิดไปเป็นแบบล่างขึ้นบน (Bottom-Up Technology) ซึ่งหมายความถึง การสร้างโดยเริ่มจากสิ่งที่เล็กที่สุดในระดับอะตอมหรือโมเลกุลขึ้นไป (Molecular Reform) นำมาจัดเรียงกันทีละอะตอมหรือทีละโมเลกุลประกอบขึ้นเป็นโครงสร้างผลึก (Crystal Structure) และทำให้เกิดสิ่งประดิษฐ์ใหม่ที่มีขนาดใหญ่ขึ้นและมีโครงสร้างเป็นระเบียบตามที่ต้องการเพื่อคุณสมบัติที่พิเศษตามที่ได้ออกแบบไว้

ในปัจจุบันเทคโนโลยีระดับนาโน (Nano Technology) ทำให้การผลิตหรือการสร้างวัสดุใหม่ถูกเปลี่ยนหลักการหรือแนวคิดไปเป็นแบบล่างขึ้นบน (Bottom-Up Technology) ซึ่งหมายความถึง การสร้างโดยเริ่มจากสิ่งที่เล็กที่สุดในระดับอะตอมหรือโมเลกุลขึ้นไป (Molecular Reform) นำมาจัดเรียงกันทีละอะตอมหรือทีละโมเลกุลประกอบขึ้นเป็นโครงสร้างผลึก (Crystal Structure) และทำให้เกิดสิ่งประดิษฐ์ใหม่ที่มีขนาดใหญ่ขึ้นและมีโครงสร้างเป็นระเบียบตามที่ต้องการเพื่อคุณสมบัติที่พิเศษตามที่ได้ออกแบบไว้

ดังนั้นฟิล์มนาโนคริสตัลคูลจึงเป็นฟิล์มที่ใช้นาโนเทคโนโลยีในการสร้างผลึกเป็นชั้นฟิล์มบาง (Nano-Crystal to Thin film Multilayer) เพื่อให้ได้คุณสมบัติพิเศษเฉพาะด้านตามที่ออกแบบไว้อย่างแม่นยำโดยสร้างแบ่งเป็นชั้นฟิล์มที่สำคัญดังนี้

1.

ชั้น Nano-Crystal UV Inhibitor ที่มีการเรียงตัวของโมเลกุลแบบพิเศษในระดับนาโนทำให้สามารถป้องกันแสง UV ได้ถึง 100% รวมถึงขยายขอบเขตการป้องกันไปถึงแสงที่มีความถี่สูงใกล้เคียงแสงยูวีได้อีกด้วย แสงในย่านนี้หรือที่รู้จักกันในชื่อแสงสีฟ้า แสงบลู หรือแสงสีน้ำเงิน(Blue light) จัดเป็นแสงที่มีพลังงานสูงที่ส่งผลกระทบต่อดวงตาของเราถ้าได้รับในปริมาณมากและเป็นเวลานานทำให้เกิดอาการตาล้า ตาแห้ง หรือตาพร่ามัวได้ โครงสร้างของชั้น UV Inhibitor นี้สามารถป้องกันแสงที่มีความยาวคลื่นตั้งแต่ 450 นาโนเมตรไปจนถึง 290 นาโนเมตรจึงครอบคลุมตั้งแต่แสงสีน้ำเงินไปจนถึงรังสี UVA และ UVB

2.

ชั้น Nano-Crystal IR Inhibitor ที่ได้รับการออกแบบให้โมเลกุลเรียงตัวในระดับนาโนเพื่อป้องกันรังสีอินฟราเรดได้สูงถึง 95 % ในช่วงกว้างตั้งแต่ย่าน 950 นาโนเมตร ไปจนถึง 2,500 นาโนเมตรซึ่งครอบคลุมช่วงของรังสีอินฟราเรดจากแสงอาทิตย์ที่ผ่านมาถึงพื้นโลก

3.

ชั้น Nano-Crystal Pigment (Inorganic Molecule) ที่ได้รับการออกแบบให้โมเลกุลของสารประกอบอนินทรีย์เรียงตัวในระดับนาโนเป็นผลึกแบบเฉพาะเพื่อสะท้อนความยาวคลื่นของแสงตามที่กำหนดเพื่อกำหนดสีของ Pigment, วางผลึกตามความหนาแน่นและรูปแบบที่ออกแบบไว้เพื่อให้ชั้นฟิล์มมีค่าแสงผ่าน (VLT) ที่แม่นยำ รวมทั้งลดแสงสะท้อนและแสง Glare ได้สูงตามที่ออกแบบไว้

ด้วยชั้นฟิล์มบางทั้งสามชั้นนี้ที่ถูกพัฒนาและสร้างขึ้นจากเทคโนโลยีนาโนซึ่งเป็นทรัพย์สินทางปัญญาเฉพาะของคอนทราสต์ จึงทำให้ฟิล์มกรองแสงติดรถยนต์และอาคารรุ่นนี้มีคุณสมบัติที่โดดเด่นในเรื่องความเย็นและความใสชัดเจน

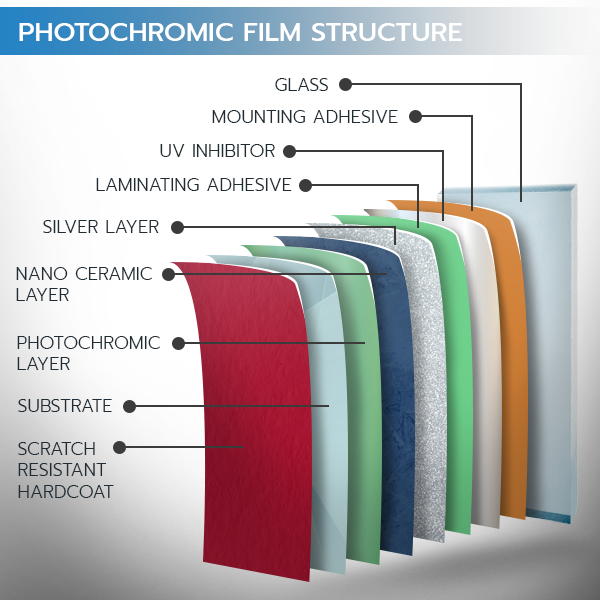

คือฟิล์มที่เปลี่ยนความเข้มสูงขึ้น(ดำมากขึ้นหรือแสงผ่านได้น้อยลง) เมื่อมีแสงเฉพาะทางจำนวนเพียงพอมาตกกระทบ ซึ่งส่วนใหญ่แสงที่ทำปฏิกริยาได้ดีก็คือแสงยูวี และแสงที่มองเห็นที่มีความยาวคลื่นสั้นซึ่งคือแสงสีน้ำเงินหรือสีม่วงนั่นเอง และเมื่อไม่มีแสงดังกล่าวตกกระทบฟิล์มนี้ก็จะกลับมาใสเหมือนเดิม เทคโนโลยีโฟโตโครมิกนี้ถูกนำมาใช้อย่างแพร่หลายในเลนส์แว่นตา ที่เรารู้จักกันในชื่อเลนส์ปรับแสงอัตโนมัติ (Photochromic lens หรือ Transition lens) และด้วยเทคโนโลยีที่ทันสมัยล่าสุดในปัจจุบันจากประเทศเยอรมัน ที่สามารถรวมชั้นฟิล์มโฟโตโครมิกเข้ากับชั้นฟิล์มเซรามิคและเพิ่มชั้นเงินเพื่อสะท้อนความร้อน จึงทำให้ฟิล์มประเภทนี้เป็นสุดยอดนวัตกรรมของฟิล์มกรองแสงกันความร้อนที่ดีที่สุดในปัจจุบัน อย่างไรก็ตามฟิล์มประเภทนี้จะมีต้นทุนการผลิตที่สูงกว่าฟิล์มทุกๆประเภท เพราะมีหลายชั้นฟิล์มคุณภาพอยู่ในฟิล์มเดียว รวมทั้งต้องใช้เทคโนโลยีขั้นสูงในการปลูกชั้นฟิล์ม

ด้วยการที่ฟิล์มประเภทนี้มีหลายชั้นจึงมีความหนาเพิ่มมากกว่าฟิล์มทั่วไป 3 -4 เท่า และมีความหนาอยู่ในเกณฑ์ของฟิล์มนิรภัย ฟิล์มประเภทนี้จึงเป็นฟิล์มนิรภัยในตัวเองซึ่งจะช่วยป้องกันการแตกกระจายของกระจกเวลาเกิดอุบัติเหตุ หรือช่วยหน่วงเวลาการโจรกรรมจากการทุบกระจกได้อีกด้วย