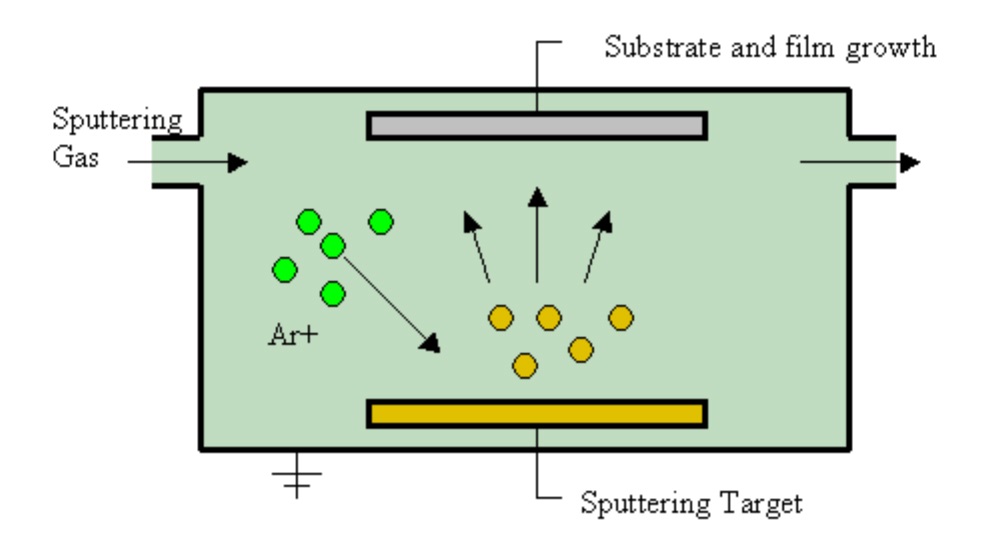

กระบวนการสปัตเตอริ่งคือกระบวนการที่ใช้เคลือบฟิล์มบาง(Thin film process) โดยไอเชิงฟิสิกส์(Physical Vapor Deposition process: PVD )ในสุญญากาศประเภทหนึ่งที่ใช้หลักการส่งผ่านโมเมนตัม โดยการปล่อยให้ผิวหน้าของของแข็ง(Target) ถูกระดมยิงด้วยอนุภาคที่มีพลังงานจลน์ อะตอมที่ผิวของแข็งจะหลุดกระเด็นออกมาเนื่องจากการชนกันระหว่างอะตอมที่ผิวและอนุภาคพลังงาน และอะตอมที่หลุดออกมาจากผิวของแข็งนี้จะไปก่อตัวบนชิ้นงาน (Substrate) เกิดเป็นฟิล์มบางขึ้นตามต้องการ

รูปแสดงหลักการเคลือบฟิล์มบางที่ผิวชิ้นงานด้วยวิธีสปัตเตอร์

ระบบของสปัตเตอริ่งได้ถูกพัฒนาและปรับปรุงด้วยเทคนิคที่แตกต่างกันมากว่า 80 ปี เพื่อให้ได้อัตราการเคลือบผิวที่สูงขึ้น, เพื่อให้ได้การเคลือบที่บริสุทธิไม่มีสิ่งเจือปน และเพื่อให้การยึดติดของฟิล์มบางแน่นหนา ด้วยเหตุนี้การผลิตฟิล์มของผู้ผลิตชั้นนำจึงใช้กระบวนการนี้เป็นหลัก

ข้อดีของฟิล์มที่ผลิตด้วยกระบวนการสปัตเตอริ่ง

- ชั้นของวัสดุที่เคลือบด้วยกระบวนการนี้จะสวย เรียบ เนียน สม่ำเสมอ

- สามารถควบคุมความหนาของชั้นเคลือบได้อย่างแม่นยำ และปรับแต่งคุณสมบัติได้อย่างกว้างขวาง

- เนื้อชั้นเคลือบมีจุดบกพร่องต่ำมากเมื่อเทียบกับวิธีการผลิตแบบอื่น จึงเหมาะกับการผลิตสินค้าระดับคุณภาพสูง

- ฟิล์มสปัตเตอร์มีประสิทธิภาพสูงมากในการต่อต้านรังสีความร้อนจากดวงอาทิตย์

- ฟิล์มสปัตเตอร์มีคุณสมบัติลดการสะท้อนเมื่อมองผ่านฟิล์มจากข้างในห้องโดยสาร คุณจึงมองผ่านฟิล์มได้อย่างชัดเจนมากกว่าฟิล์มธรรมดาทั่วไป